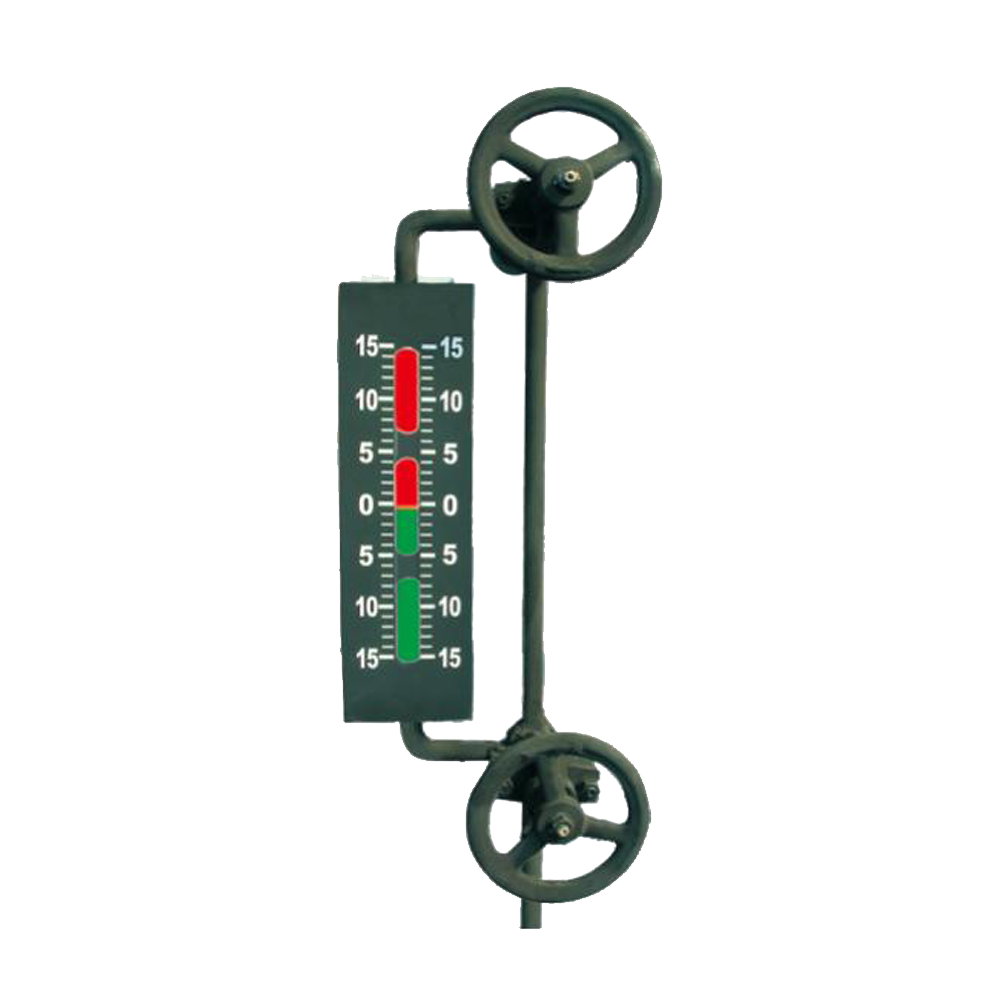

The double-chamber balance container is used in conjunction with a water level indicator or a differential pressure transmitter to reflect the mass (weight) water level in the steam drum during boiler startup, shutdown and normal operation.

Structural principles

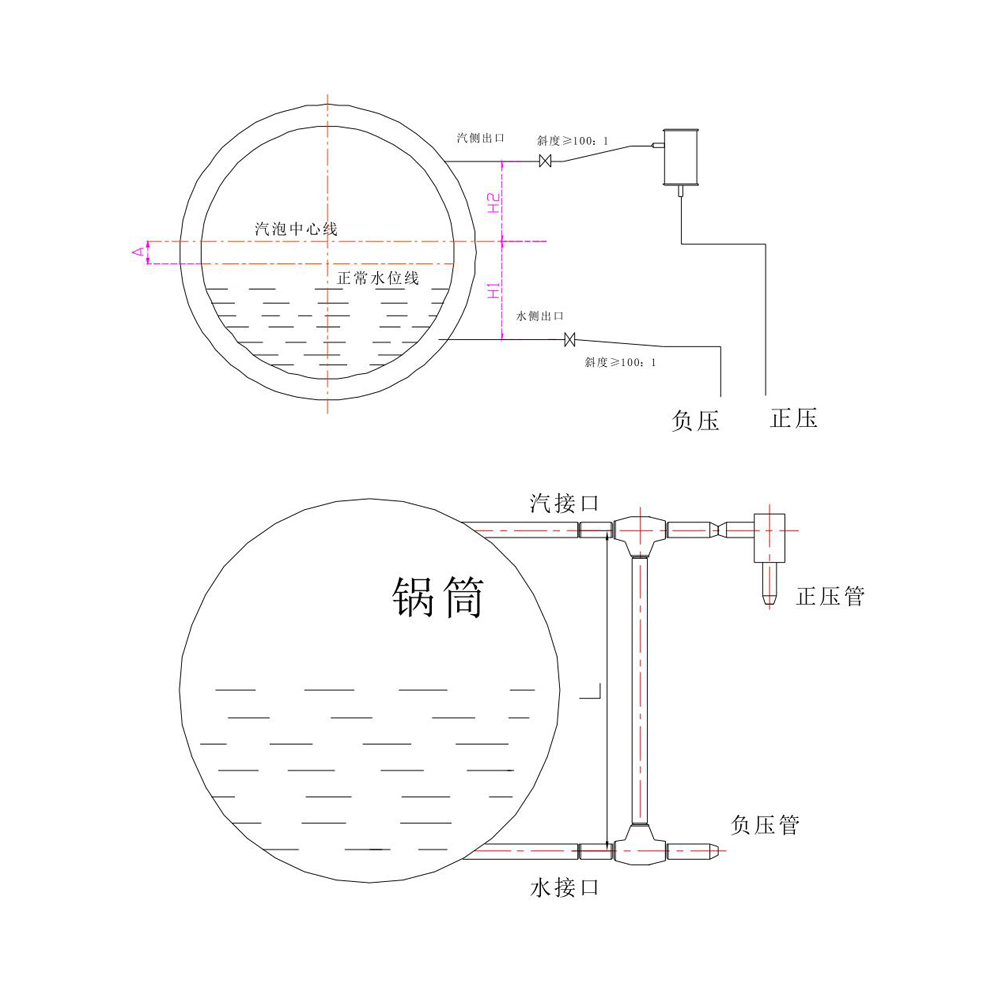

The balance container consists of a positive pressure pipe, a negative pressure pipe, a down pipe, a funnel, a water cup, a connecting pipe, etc. The balance container is directly connected to the boiler steam and water. During the working process, the heat released by the condensation of saturated steam heats the positive pressure pipe and the negative pressure pipe at the same time, and the outer insulation of the balance container can reduce the loss of heat, thereby reducing the weight of the water in the positive pressure pipe under any working conditions. are approximately equal to the weight of the water in the bubble; when the water level in the drum is constant, no matter how the pressure in the drum changes, the pressure changes in the positive pressure pipe and the pressure pipe in the negative pressure pipe are equal, so the difference in the output of the double-chamber balance container Pressure remains unchanged. Once the water level changes, the output differential pressure also changes accordingly, which can display the water level in the container in a timely manner.

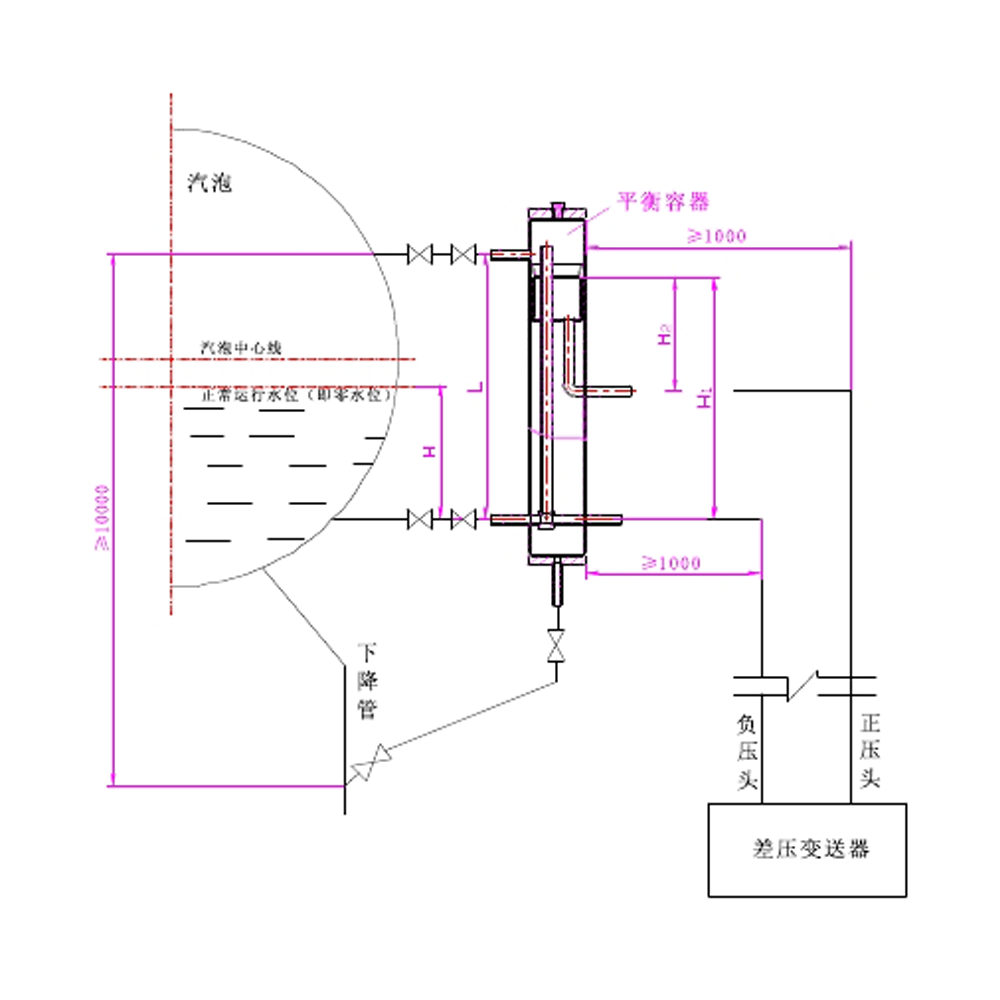

Installation instructions

1. During installation, the balance container must be kept vertical and the sampling pipe must be horizontal, but the steam sampling pipe can be tilted upward.

2. The condensate water pipe should be connected to the downpipe with the fastest water circulation.

3. The distance between the two bent pipes of the balancing container connecting pipe should be greater than 1000mm.

Installation diagram

.jpg)

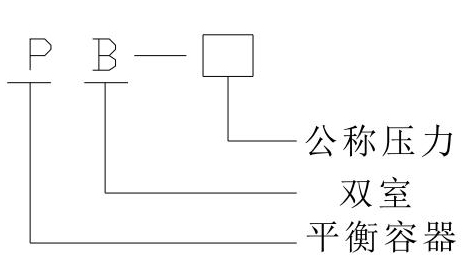

Model description

Senior engineer

Senior engineer