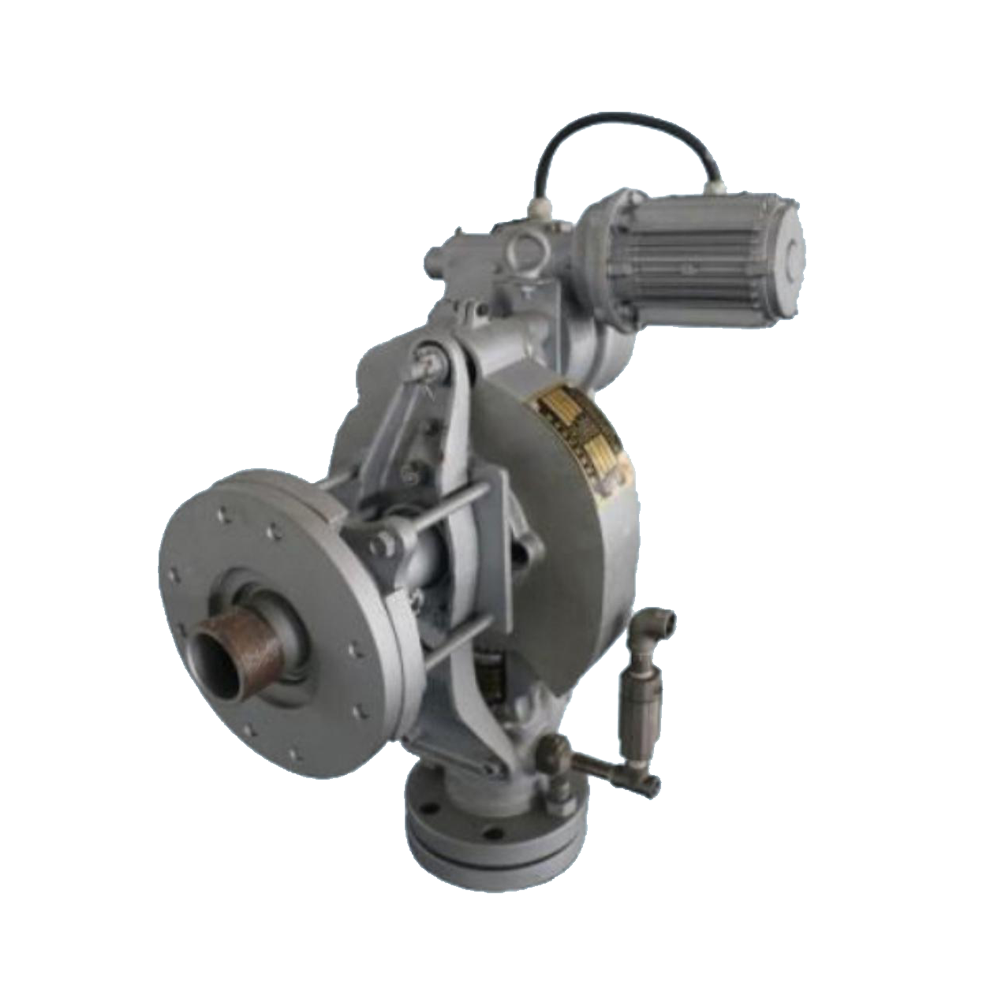

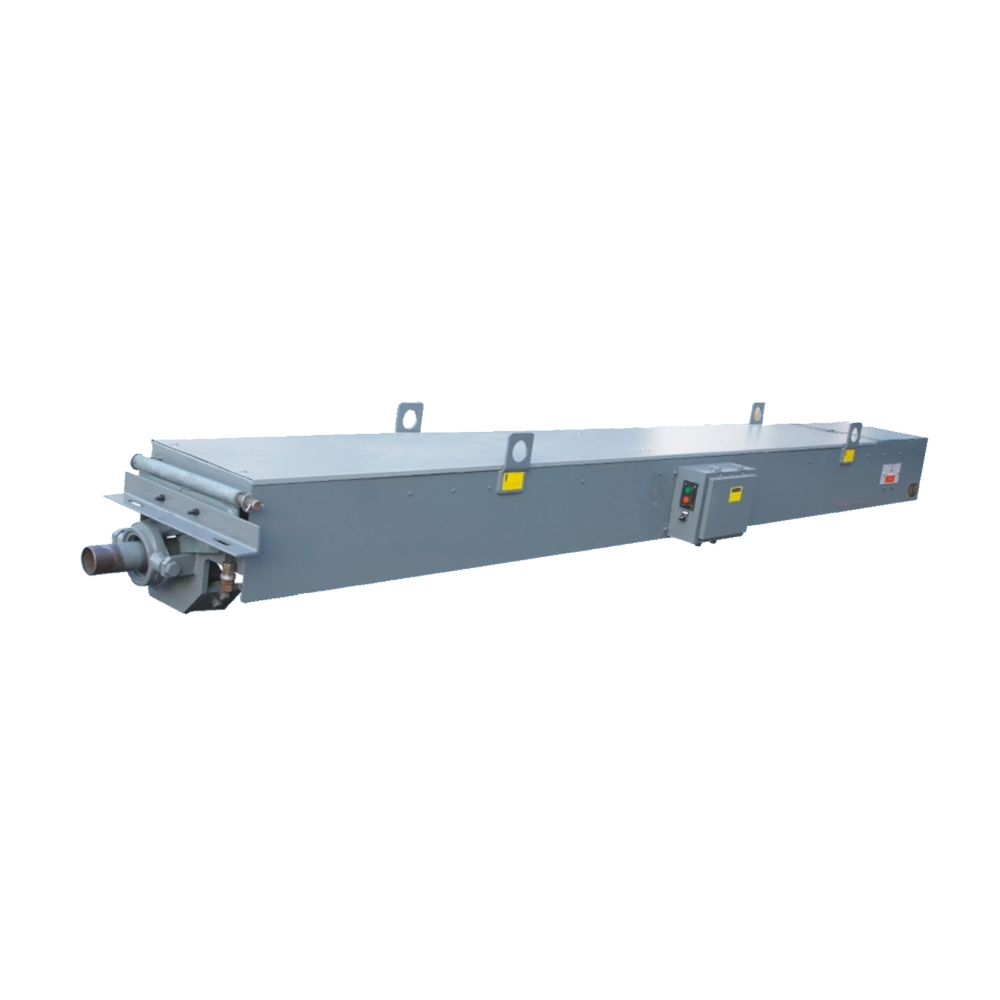

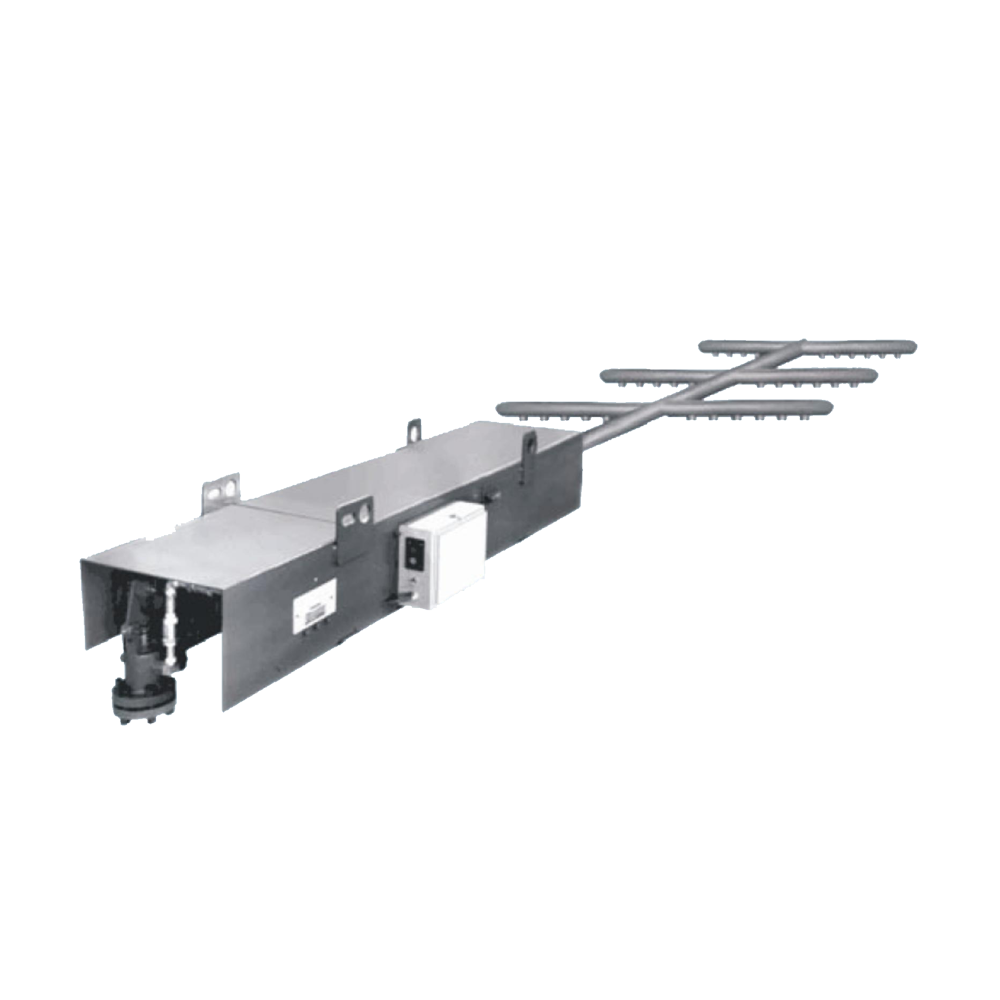

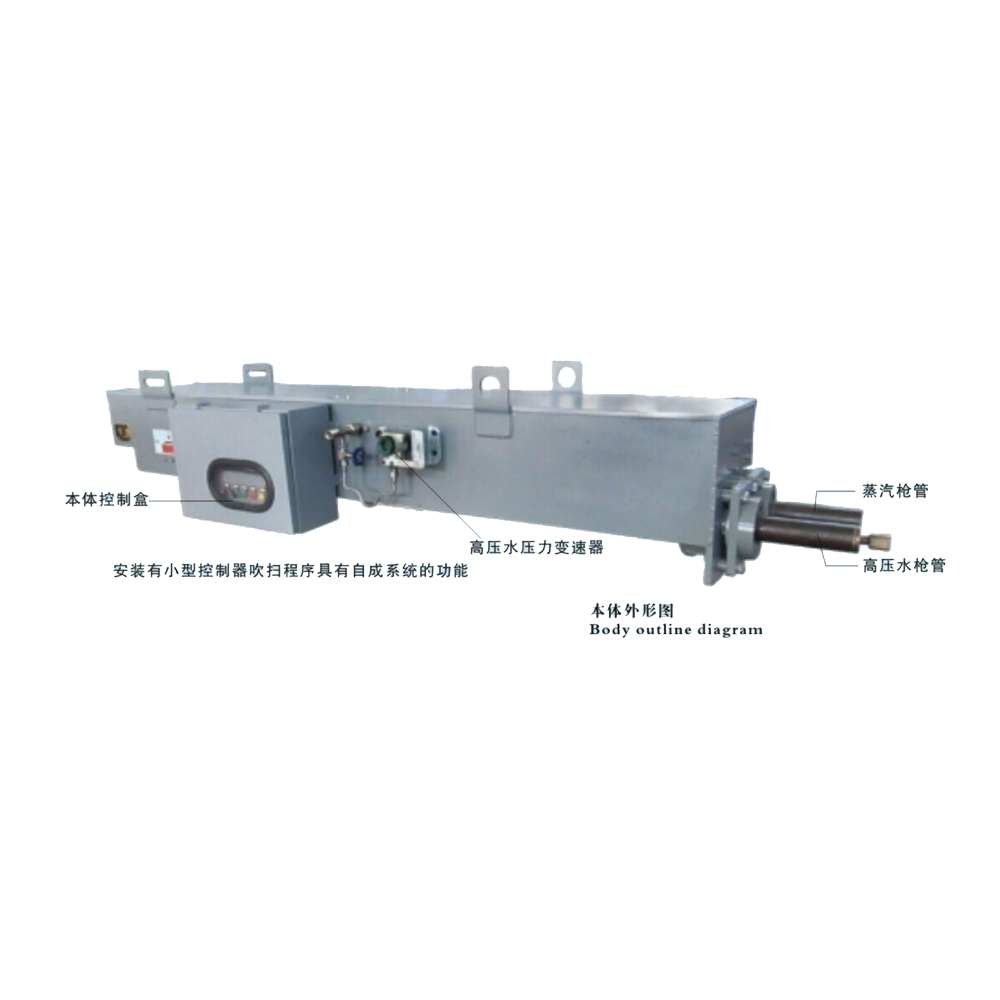

HX-GX fixed rotary soot blower is mainly used for quick installation boilers, marine boilers, waste heat boilers and oil furnaces; it is also used to purge the low temperature areas of large boilers (reheaters, economizers, tubular preheaters, Dust accumulation and coking on the heating surface (flue gas recirculation and dust removal area).

Its features are as follows:

※Installation method: vertical, horizontal.

※The change of cam arc determines the purge range.

※Soot blowing medium: superheated steam, compressed air.

※The soot blowing pressure can be changed by changing the position of the pressure regulating plate.

※Unique flexible valve seat design does not change due to temperature difference

will affect the sealing effect.

※The supporting plate in the furnace can prevent the barrel from bending.

※The barrel is connected with the main body coupling sleeve to ensure the free rotation of the barrel.

※The floating packing chamber can ensure good sealing between the sootblower and the boiler and prevent flue gas from escaping.

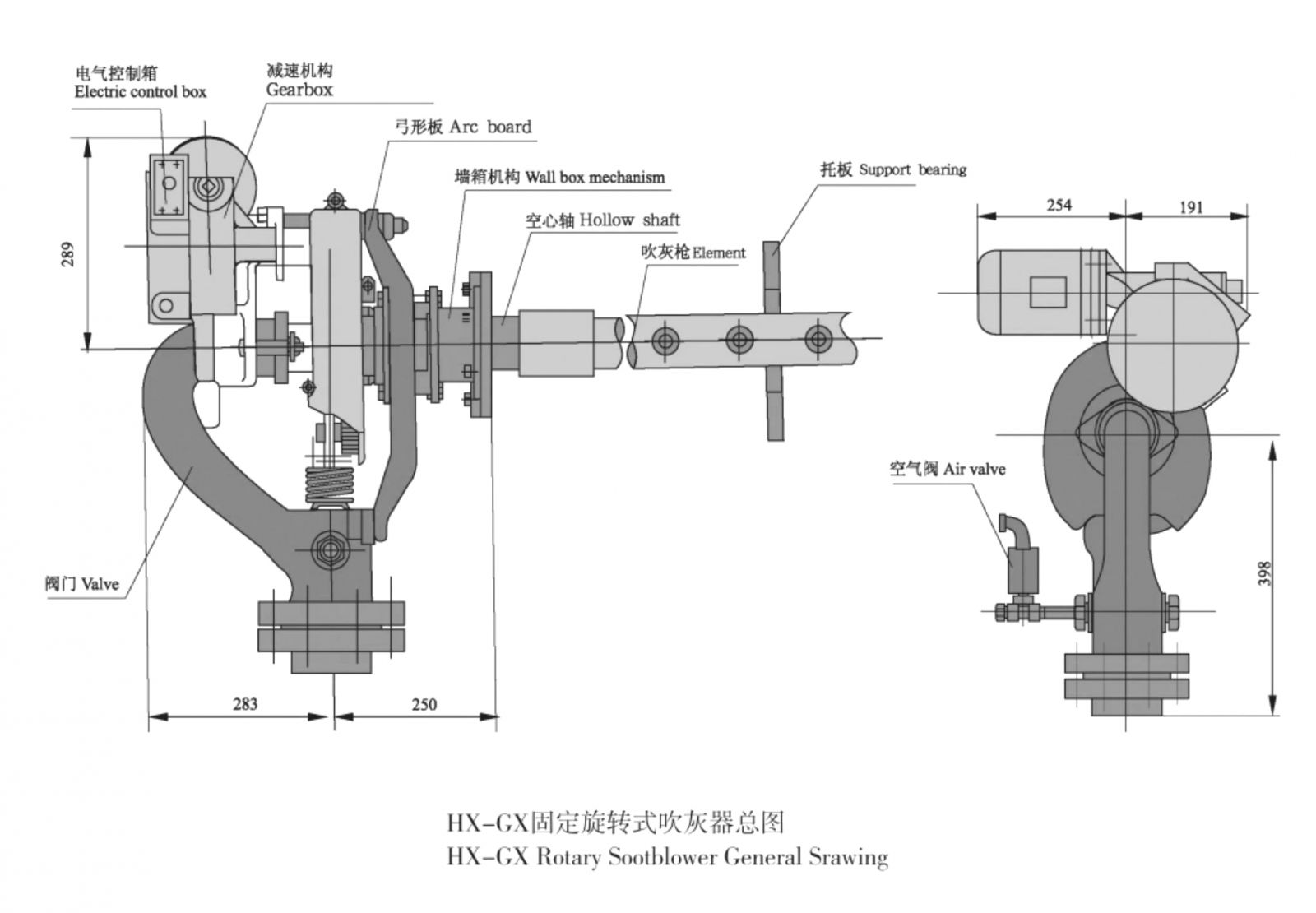

HX-GX soot blower structure introduction

HX-GX soot blower is mainly composed of gooseneck valve, hollow shaft, soot blowing gun, reduction transmission mechanism and arcuate plate, electrical control box, furnace wall interface device, furnace supporting plate, etc.

Senior engineer

Senior engineer