Uses

The single-chamber balance container is used in conjunction with a water level indicator or a differential pressure transmitter to reflect the mass (weight) water level in the steam drum during boiler startup, shutdown and normal operation.

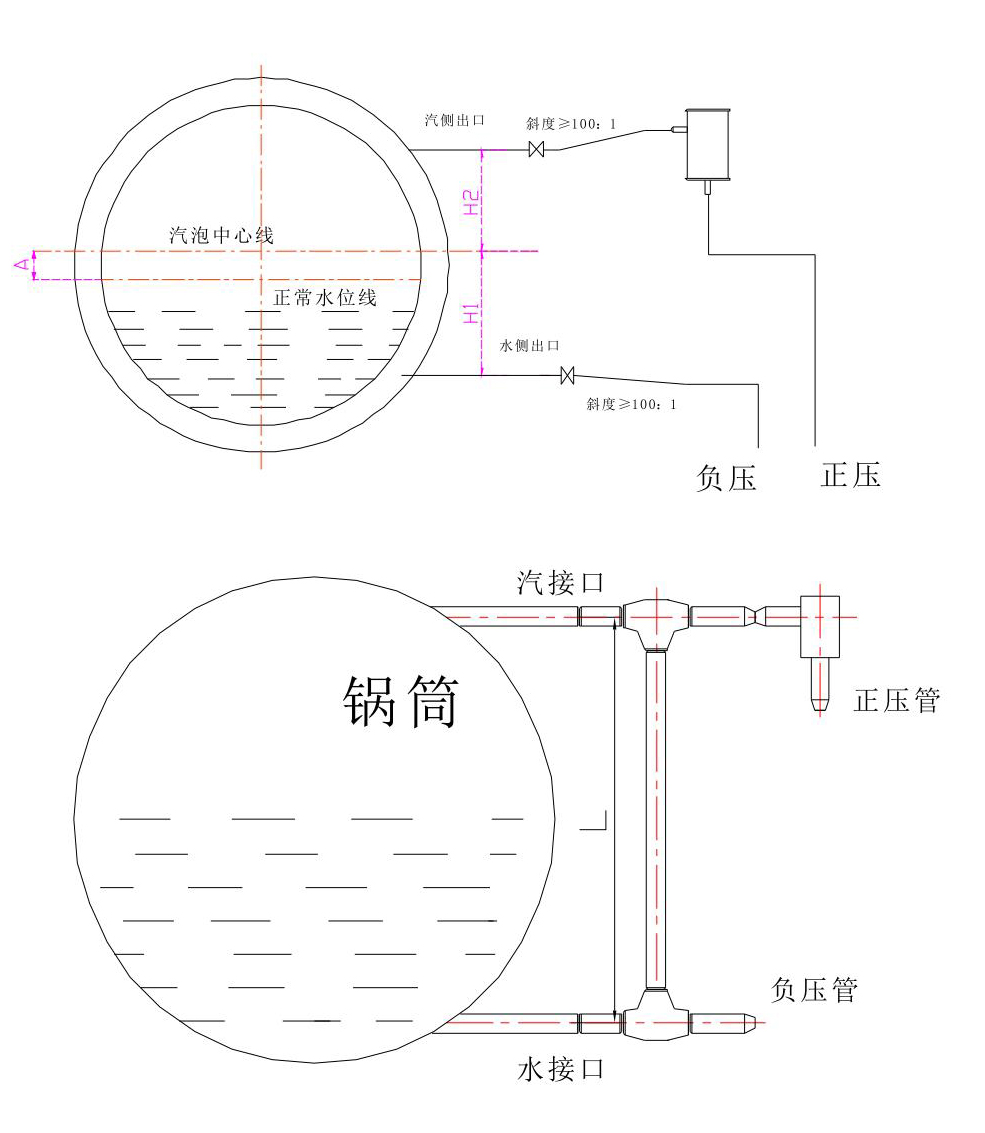

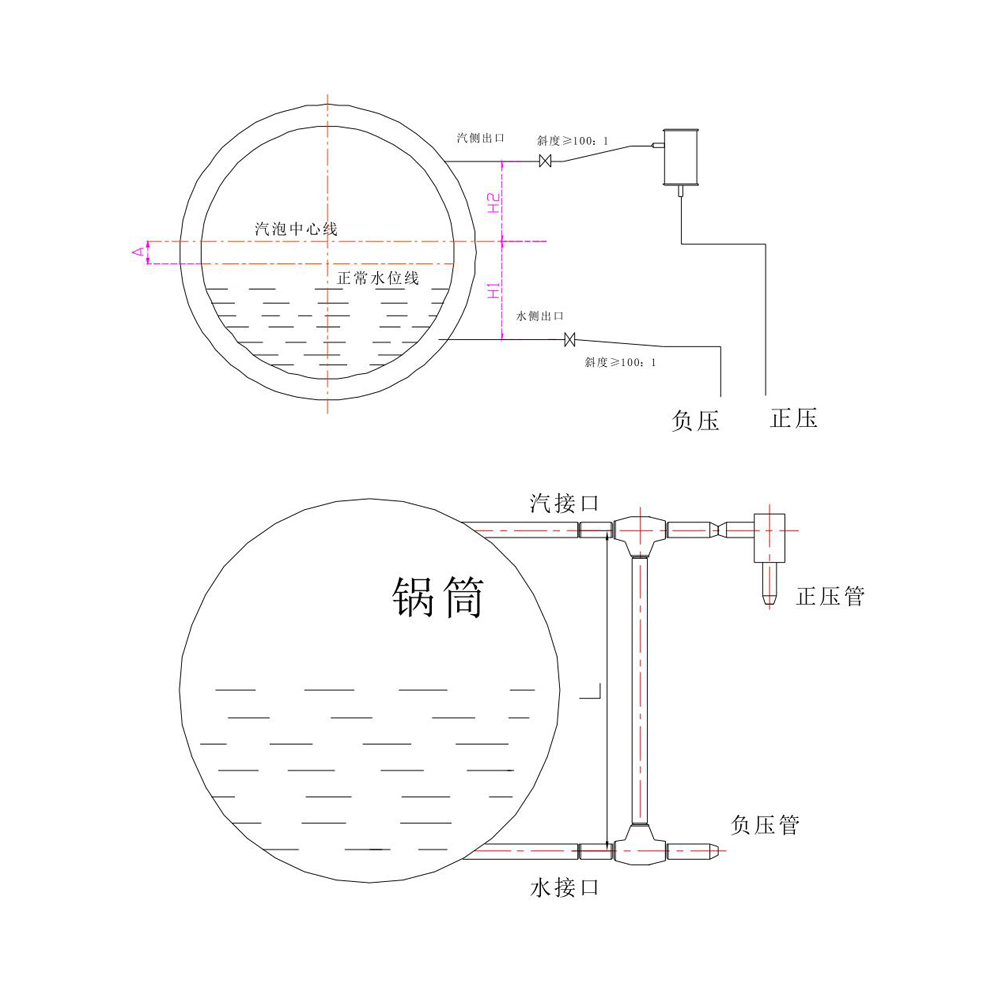

The principle of measuring water level

A pipe is led from the sampling hole on the steam side of the drum to the balance container. The saturated steam entering the balance container continuously condenses into water. The excess water flows back to the drum from the sampling pipe due to the overflow principle, keeping the water level in the balance container constant. Therefore, the positive pressure head of the differential pressure transmitter remains unchanged due to the constant water column in the balance container, while the negative pressure head changes with the change of the drum water level.

Installation instructions

1. A stop valve should be installed between the balance container and the container to facilitate disassembly and repair;

2. Except for the condensation container, all others need to be insulated. The condensation container can quickly condense the saturated steam, and can continuously replenish the condensed water to keep the water quality constant.

3. The balancing container must be installed vertically.

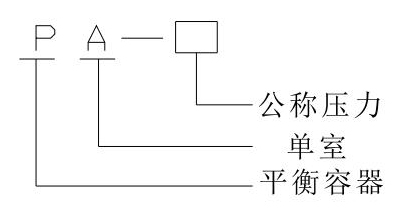

Installation diagram

Model description

Senior engineer

Senior engineer