Overview

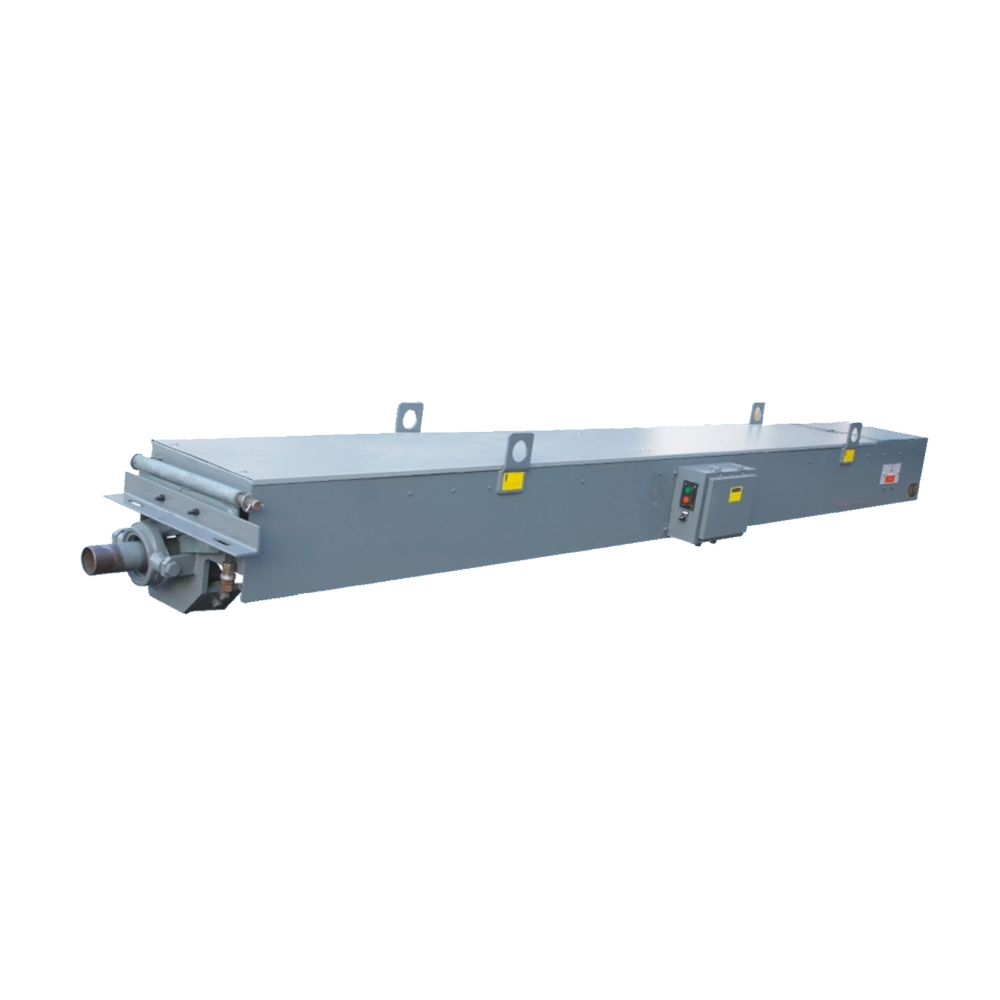

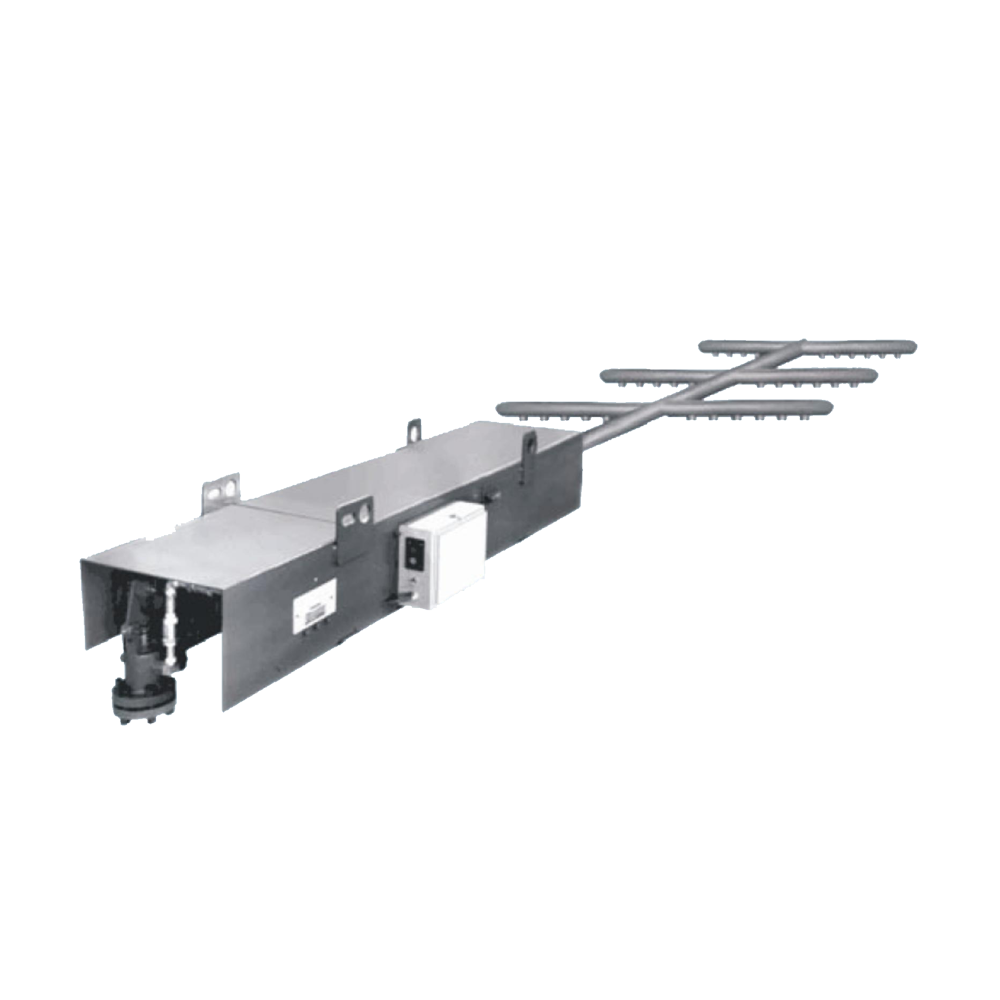

UHC series side-mounted magnetic float level gauge can be used for medium level detection in various towers, tanks, tanks, spherical containers, boilers and other equipment. This product has the characteristics of simple structure, easy operation, low maintenance, good sealing, safe use, full range measurement without blind spots, eye-catching display, intuitive and accurate readings, and large measurement range.

UHC series side-mounted magnetic float level gauge can be used with liquid level alarm control switch and magnetic remote transmitter. When used in conjunction with the liquid level alarm control switch, it can realize liquid level alarm and liquid level control functions; when used in conjunction with the magnetic remote transmitter, it can output 4~20mADC standard signals to achieve remote detection, indication, recording and control.

UHC series side-mounted magnetic float level gauge is widely used in liquid level measurement and control in the production process of electric power, petroleum, chemical industry, metallurgy, environmental protection, shipbuilding, construction, food and other industries. When the operating temperature is higher than 300°C, thermal insulation material is installed between the Liquid Level Gauge cylinder and the panel.

Working principle

The main principles of the side-mounted magnetic float level meter are the connector principle, the magnetic coupling principle and Archimedes' theorem. According to the principle of the connector, the liquid level in the cylinder is the same as the liquid level in the container equipment; according to Archimedes' theorem, the buoyancy generated by the float equipped with permanent magnet steel in the liquid balances with the gravity, and the float floats in the liquid. On the surface, when the liquid level in the container under test rises and falls, the floating ball in the Liquid Level Gauge cylinder rises and falls with the liquid level, and drives the flip column or flap on the indicator outside the cylinder (commonly known as the flip plate rack) to flip through magnetic coupling. When it rises, the flip column or flap changes from white to red; when it goes down, the flip column or flap turns from red to white, with vapor white and liquid red indicating the liquid level.

Senior engineer

Senior engineer