Overview

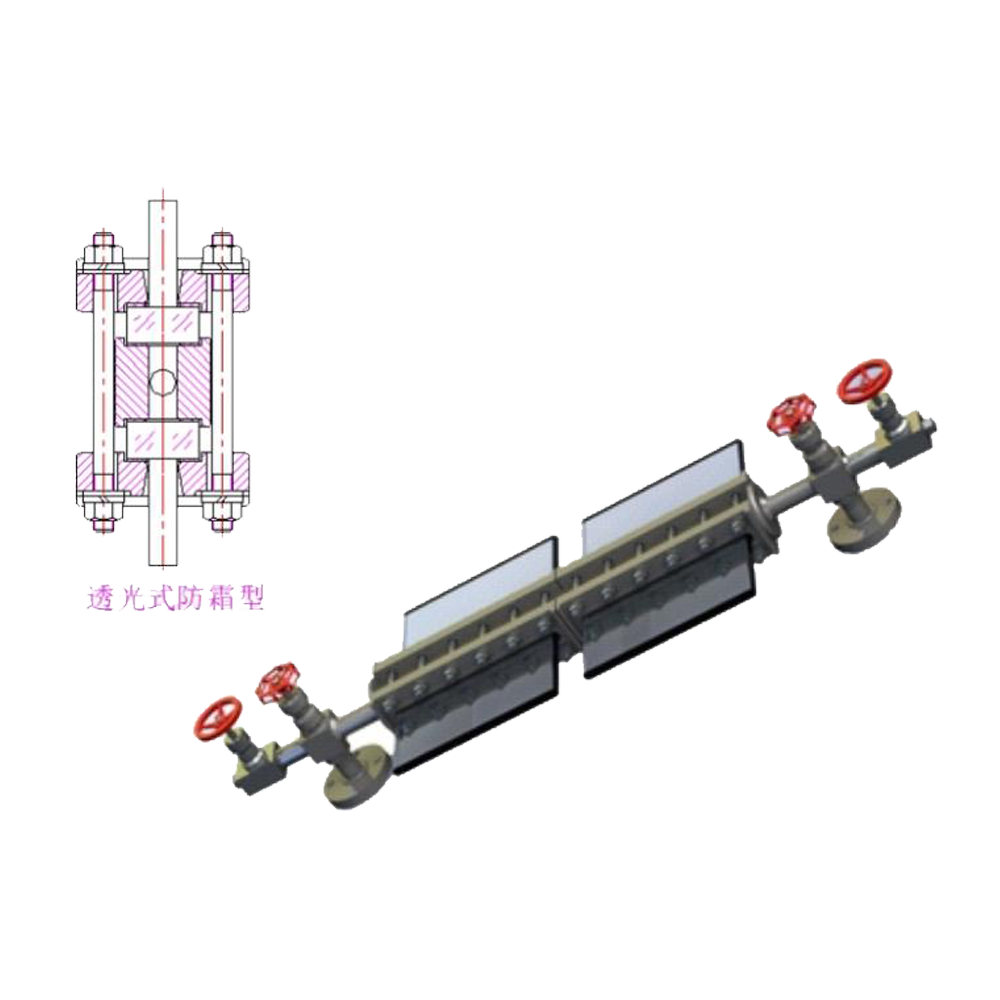

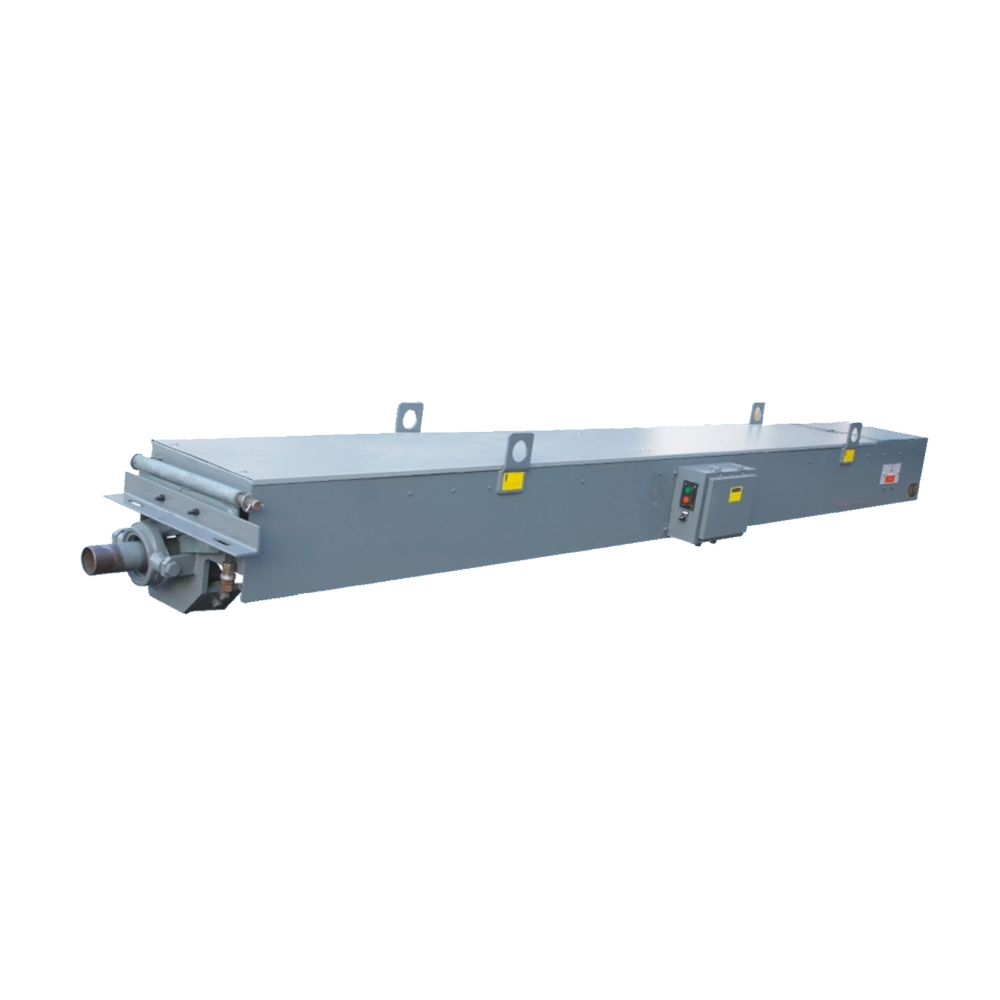

The UBF series frost-proof Glass plate Liquid Level Gauge is suitable for low-temperature media (below 0°C). It is specially designed to solve the problem that low-temperature media are prone to condensation and frost, which causes the general Glass plate Liquid Level Gauge to be unable to measure. The product has a simple structure, is easy to operate, and is safe to use. It is equipped with an insurance steel ball to prevent accidents.

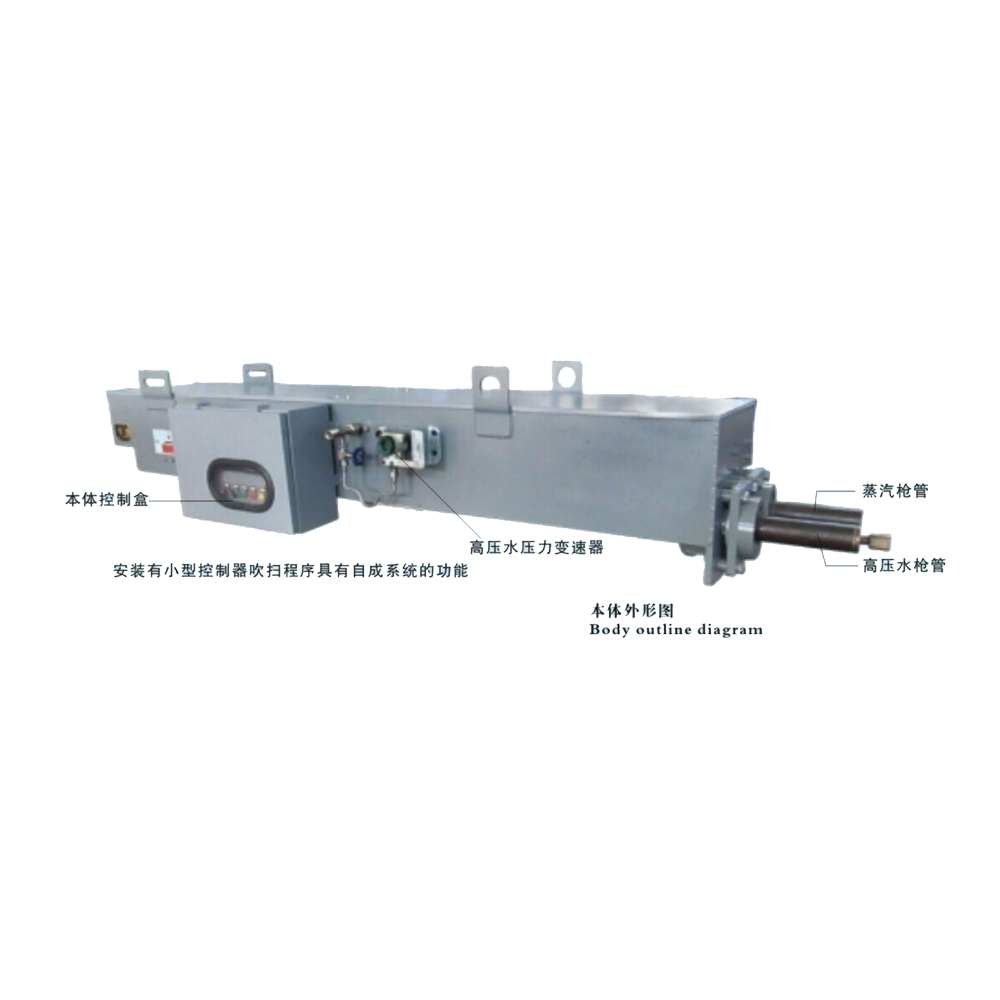

Structural principles

UBF series frost-proof Glass plate Liquid Level Gauge consists of a meter body, an upper valve, a lower valve, a drain valve (or drain flange), a vent valve (or vent plug), and an anti-frost fin. The upper and lower mounting flanges are connected to the corresponding flanges on the container to form a connector. The actual height of the liquid level in the container can be directly observed through the anti-frost fins. Safety protection is provided in the upper and lower valves.

Device, when the glass plate is accidentally damaged, the protective steel ball will automatically seal under the action of the internal pressure of the container to prevent the liquid in the container from continuing to leak out.

In addition to using the connector principle, UBF series frost-proof Glass plate Liquid Level Gauge also applies the temperature gradient principle in physics: when a material that transmits temperature contacts a low-temperature source, the farther away from the low-temperature source, the closer the temperature is. This effectively solves the problem of anti-frost. Since the temperature-conducting material (anti-frost fins) is transparent, the liquid level can be clearly observed through the anti-frost fins.

Senior engineer

Senior engineer