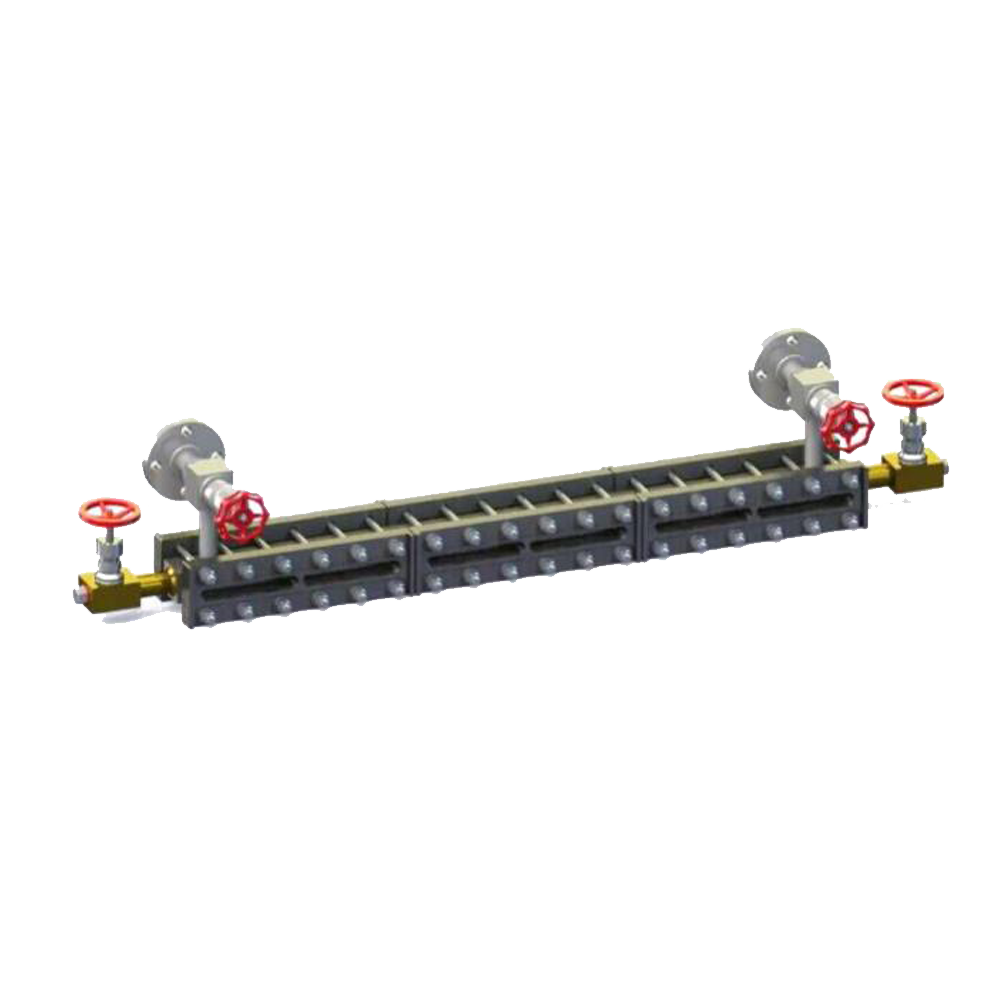

Overview

The UB series is a direct-reading instrument used to monitor liquid levels in low-pressure boilers, pressure vessels and pipelines. The product has a simple structure, is easy to operate, and is safe to use. It is equipped with an insurance steel ball to prevent accidents. In addition, for corrosive media (only UBDT series and UBDTM series can be selected), high-quality mica sheets are used to prevent the medium from corroding the Glass plate to ensure the observation effect and the service life of the Liquid Level Gauge.

Product technical parameters

Installation center distance: 200mm~3500mm Visual range:

Series with blind zone: 200mm~3260mm

Series without blind zone: 200mm~3500mm

Nominal pressure: ≤5.0MPa;

Working pressure: <2.0MPa

Working temperature: -20℃<200℃

Valve self-locking pressure: ≥0.25MPa

Flange standard: HG20592-20635-2009, other standards and special requirements need to be specified by the user.

Material: carbon steel, 304SS, 316SS (can be produced according to user requirements)

Heating steam pressure: ≤1.0MPa (can be designed according to user requirements)

Heating interface: R1/2" thread (can be designed according to user requirements) Color display:

UBD series: single color (natural color of medium)

UBS series: double color (liquid phase is natural color of medium, vapor phase is red)

Glass material: borosilicate glass<200℃

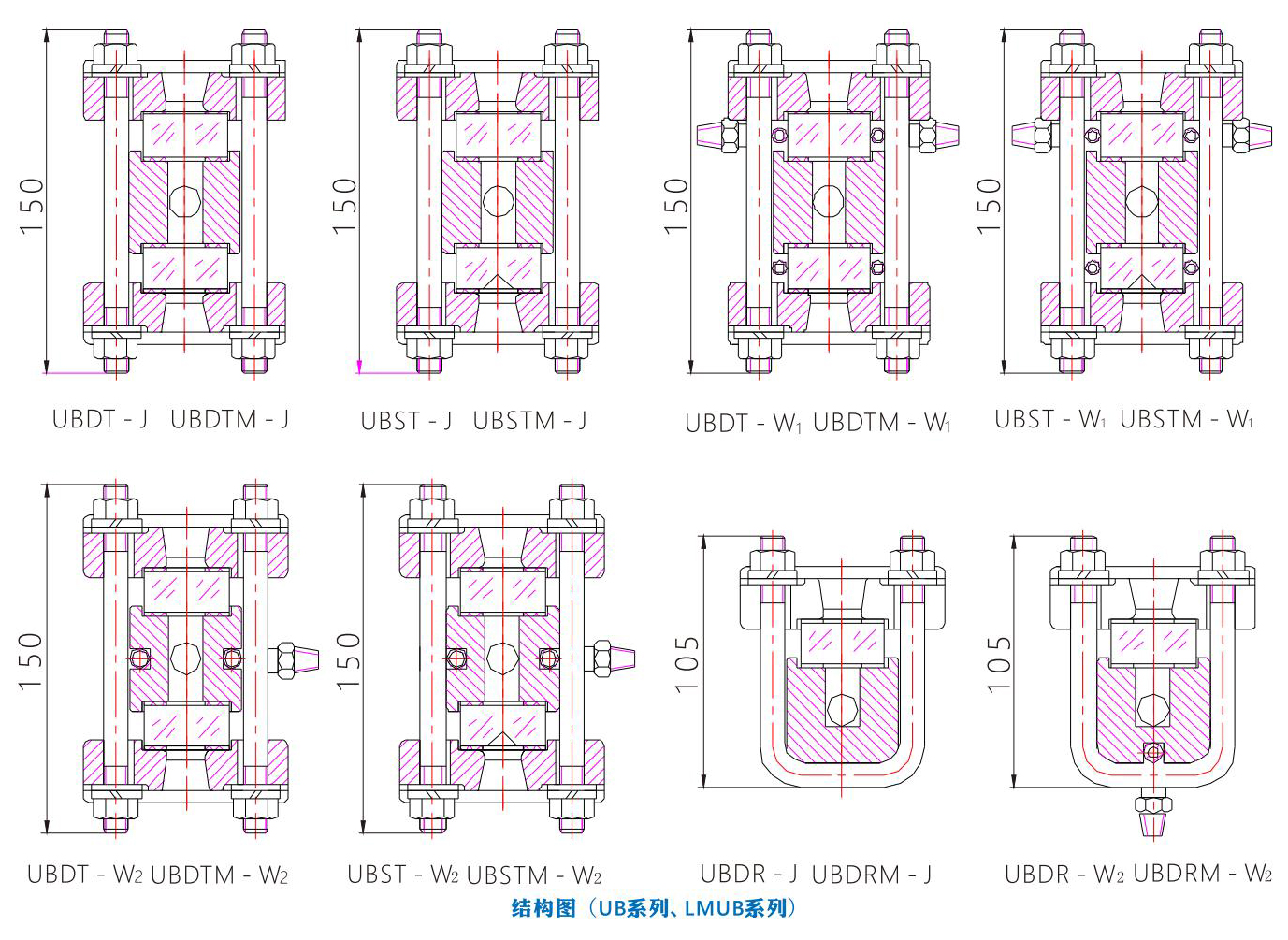

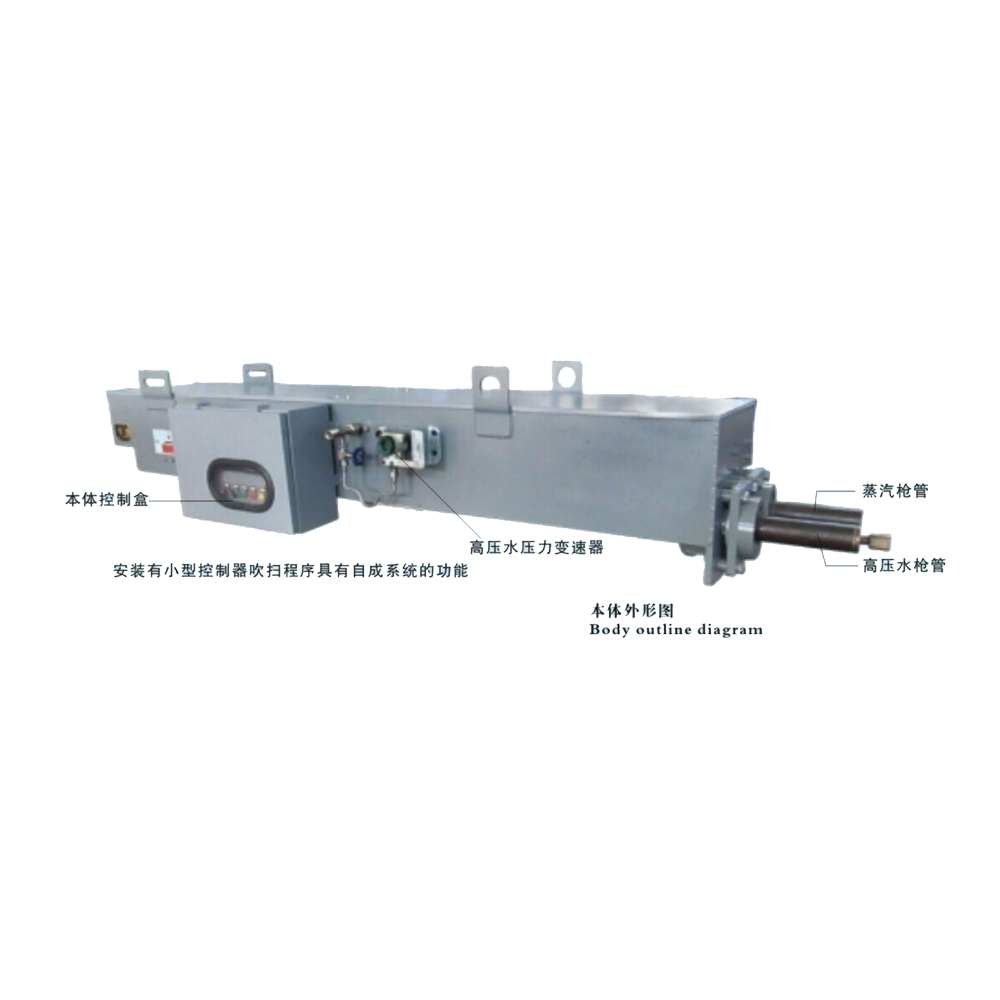

Structural principles

UB series glass Liquid Level Gauge consists of a meter body, an upper valve, a lower valve and a drain valve. The upper and lower mounting flanges are connected to the corresponding flanges on the container to form a connector. The actual height of the liquid level in the container can be directly observed through the Glass plate . Safety protection devices are installed in the upper and lower valves. When the Glass plate is accidentally damaged, , the protective steel ball automatically seals under the action of the internal pressure of the container to prevent the liquid in the container from continuing to leak.

.jpg)

Senior engineer

Senior engineer